The valve is a control component in the fluid delivery system. It has functions such as cut-off, regulation, diversion, prevention of backflow, shunting or overflow relief. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metals and radioactive media, and are widely used in our daily life as well as various industries. In order to extend the service life of the valve, we need to do a good job in the storage of the valve. Next, Adamant Valves will tell you how to keep the valve.

The purpose of good storage of the valve is to prevent it from being damaged or of reduced quality during storage. In fact, improper storage is one of the important reasons for valve damage. Here are some things we need to pay attention to in valve storage:

1 Valve storage should be well organized that the valves should be neatly arranged, and do not let the valve connection surface touch the ground. This is not only for aesthetics, but mainly to protect the valve from damage.

2 Unnecessary losses such as hand wheel breakage and stem damage caused by improper storage and handling should be avoided.

3 For valves that are not used for a short period of time, asbestos filler should be taken out to avoid electrochemical corrosion and damage to the valve stem.

4 Check the valve that has just entered the warehouse, and wipe it clean before store it.

5 The inlet and outlet of the valve should be sealed with wax paper or plastic sheet to prevent dirt from entering.

6 For those valves that are prone to rust in the atmosphere, the surface should be protected with anti-rust oil. For sanitary valves, however, you don’t need to worry about rust prevention, because the part of the valve that is in contact with the medium is usually made of 304SS or 316 stainless steel, which is not easy to cause corrosion or fall off.

7 Valves placed outdoors should be covered with rain-proof and dust-proof items such as linoleum or crepe. The warehouse where the valves are kept should be clean and dry.

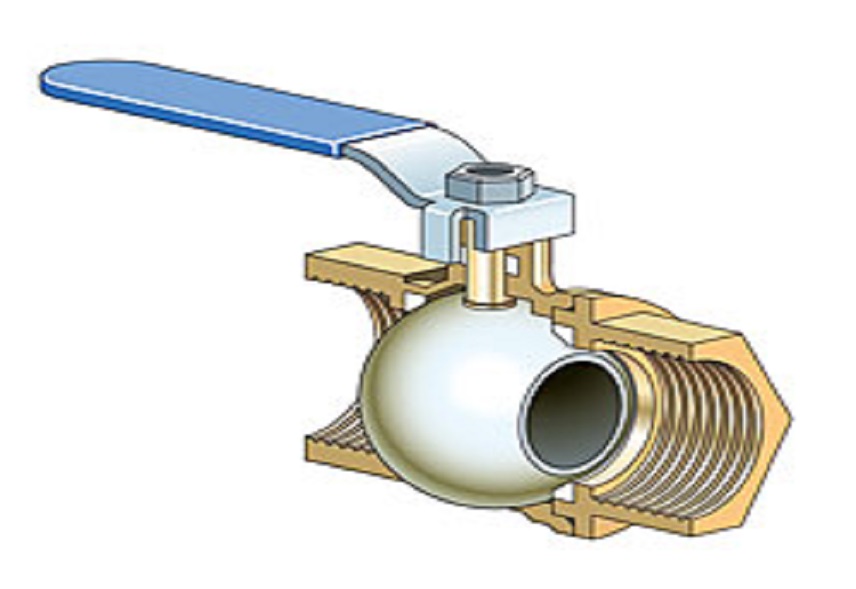

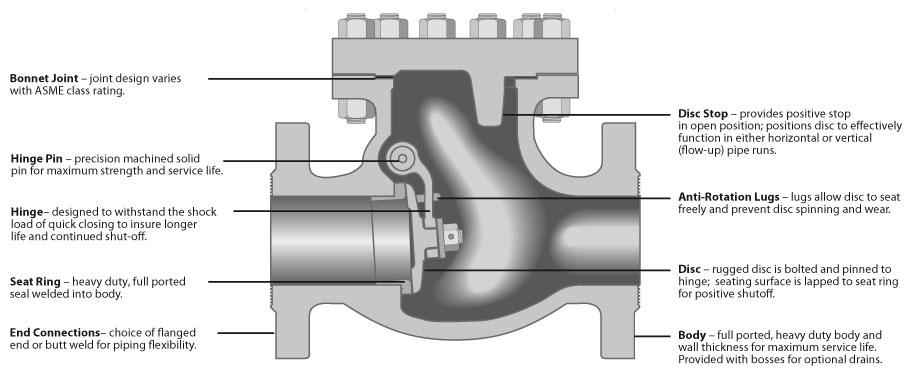

At last, here is a short video introducing the three main types of valves, including check valve, ball valve and butterfly valve. Please have a look and hope would be helpful.

Adamant Valves is a professional sanitary valves manufacturer specialized in manufacturing a wide range of sanitary butterfly valves and sanitary ball valves. If you are interested, please visit our website http://www.adamantvalves.com/ for more information.