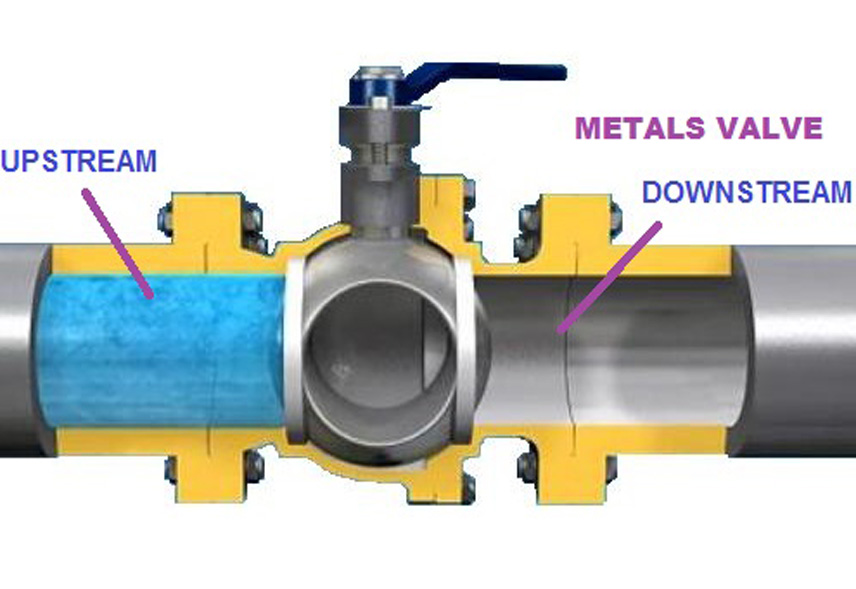

A Sanitary ball valve is a type of valve opened by turning handles attached to balls inside the valves. A ball valve is durable and usually works to achieve perfect shutoff even after years of disuse. It has a wide range of applications, such as pharmaceutical production, winemaking, dairy products, fine chemicals, pharmaceuticals, and bioengineering in major enterprises. And it is suitable for many media, such as liquid, gas and steam.

Sanitary ball valves are mostly stainless steel. Why is it made of stainless steel? The reason is simple, stainless steel is not only a relatively cheap material, but also durable and will not rust. This material is very environmentally friendly and hygienic, suitable for different industrial production. When customers choose valve products, they should know exactly what model they need, and do not cause unnecessary trouble to themselves because of the wrong selection. Most reliable valve companies provide consulting services. If customers encounter problems, they can consult relevant personnel for help before placing an order.

Further Reading: How to choose the different steel materials of sanitary valves?

In addition to general-purpose screwdrivers, adjustable wrenches and hammers, the common tools required for disassembly and assembly of sanitary ball valves are as follows:

1. Non-adjustable wrench: It can only turn a nut or bolt of one specification. Compared with an adjustable wrench, this wrench is not easy to damage the nuts and bolts. It is divided into open-end wrench, integral wrench and Torx wrench.

2. Sanitary Ball Valve Socket Wrench: It is composed of Torx wrenches of different sizes. They are used in difficult positions.

3. Locking wrench: Locking wrench is divided into fixed hook wrench, movable hook wrench and U-shaped locking wrench. It is used on the nut.

4. Sanitary ball valve special wrench: there are frying wheel wrenches and throwing drummers, etc. The ratchet wrench does not need to change the angle when it is pulled. A torque wrench is also called force measuring beckoning. When the force is pulled, the elastic rod is deformed, and the greater the force, the greater the deformation. The deformation of the elastic sweat makes the dial move, and the amount pointed by the pointer is the measured torque. This kind of wrench can avoid excessive force and damage parts. It is often used in electric ball valves to measure the preload of gaskets.

For more information, please visit https://www.adamantvalves.com/.