Introduction

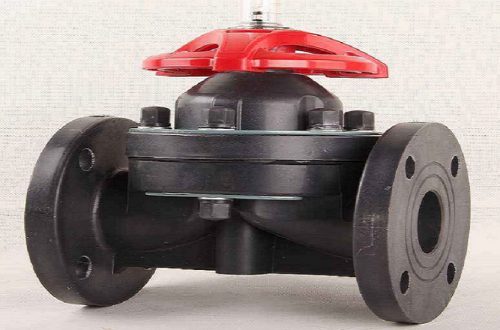

A sanitary diaphragm valve is composed of a sanitary diaphragm and a pneumatic actuator, which is powered by compressed air to regulate the flow of fluid medium in the processing pipeline.

Structure

The structure of the sanitary diaphragm valve is very different from the general valve structure. It relies on a soft rubber membrane or plastic membrane to control the fluid movement. Commonly used diaphragm valve materials are divided into cast iron diaphragm valve, cast steel diaphragm valve, stainless steel diaphragm valve, and sanitary diaphragm valve material diaphragm valve.

Principle

The closing and opening of the sanitary diaphragm valve are achieved by the pressure from the pipeline acting on the reinforced rubber diaphragm. When the pressure medium enters the valve control chamber, the diaphragm is pressed down and the valve channel is closed. When the control chamber pressure is discharged to the atmosphere or the downstream pipeline, the diaphragm rises and the valve channel is opened. The valve has no valve stem, gasket, directional seat, etc., and the moving part in the channel is the diaphragm, so there is no corrosion and locking, and it has higher stability. A variety of structural forms and control forms can be applied to a variety of fluid control needs.

Further Reading: How Do Sanitary Diaphragm Valves Work?

Advantages

The advantage of the sanitary diaphragm valve is that its operating mechanism is separated from the medium passage, which not only ensures the purity of the working medium, but also reduces the possibility of the medium in the pipeline impacting the working parts of the operating mechanism.

In addition, there is no need for any form of separate seal at the valve stem, unless it is used as a safety feature in the control of hazardous media using a sanitary diaphragm valve.

In the diaphragm valve, since the working medium is only in contact with the diaphragm and the valve body, a variety of different materials can be used for both. Therefore, the valve can ideally control a variety of working media, especially for media with chemical corrosive or suspended particles.

Application

Because the sanitary diaphragm valve adopts a valve body with corrosion-resistant lining and a corrosion-resistant diaphragm, no stuffing box structure, the throttling element is an elastic diaphragm, and the valve body flow path is smooth, so the pneumatic diaphragm valve has a small negative force. It has the advantages of large flow, no leakage, convenient and reliable, fireproof and explosion-proof, and is widely used in the flow regulation of the medium that is not allowed to pollute in the industrial automation system.

For more information about sanitary diaphragm valves, please visit http://www.adamantvalves.com/.