In the previous weeks, we have talked about many interesting things of sanitary valves, ball valves and butterfly valves. Today, our focus is the “belated” check valves.

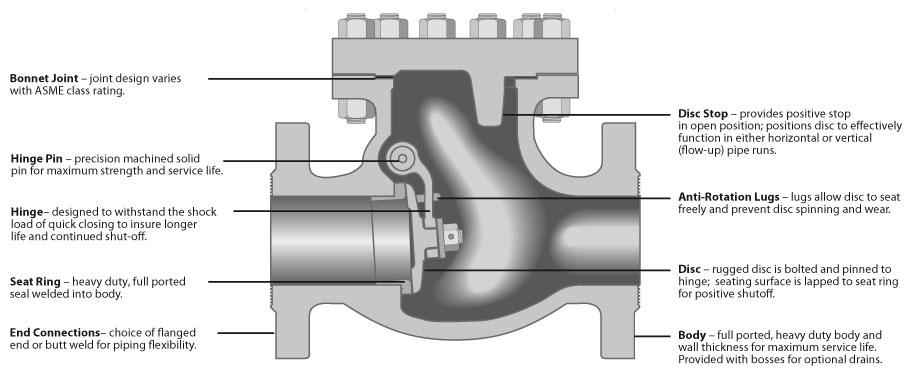

Check valves, also known as one-way valves, are used to prevent the pipeline water back in the media. Check valves have two ports, one for fluid to enter and the other for exit. Check valves work automatically and most of them are not controlled by a person or any external control. Accordingly, most check valves do not have any valve handle or stem. Check valves are used in a wide range of applications, both as sanitary check valves and industrial check valves. Here is a short video about how the check valve works.

(full version: https://youtu.be/X14nww4wuAk)

The main purpose of a check valve is to prevent back flow in the process. Check valves can lighten the load of a water pump, prevent overspill and even guard against gray water contamination. Thus, check valves can be one of the most important elements of a plumbing system. So it is necessary to test the check valves regularly, which can help ensure the safety and function of the entire plumbing system. So let’s see the specific steps to test sanitary check valves.

First, of course, you have to shut off the fluid supply to the check valve. Then follow the supply line back (there is an arrow of check valves) to find the next valve and switch it off. And you need to wait 15 to 20 minutes for the pressure to ease.

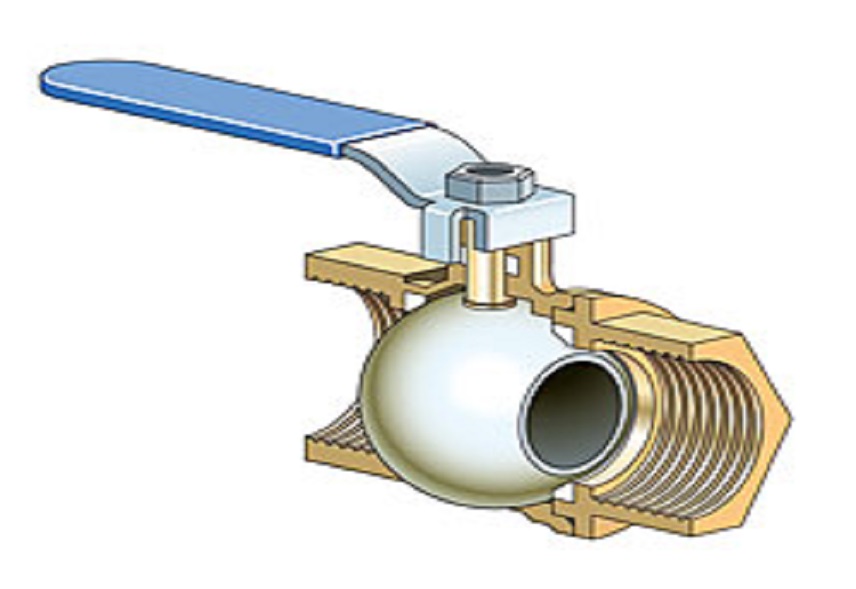

Second, you should search the valve for debris by tapping its side with some tools such as the handle of a screwdriver, wrench or small hammer. A rattling sound means the check valve is fine, but a grinding or squeaking noise indicates that the valve is stuck on some form of debris or leaking. Then, you can remove the top of the valve and check the valve inside directly. Normally, there is only a ball-pin inside the valve. So if there is anything else, remove them and replace the top of the valve.

Third, you should ask someone else to help you restart the fluid supply for five seconds before shutting it down again. At the same time while your assistant turn on the fluid supply, put your hand on the valve and you ear next to the valve. Any sound of fluid running indicates a leak. Most of the time, however, you will hear and feel a gentle “click” sound as the valve closes and water will cease running through the valve as the water is shut off.

Please visit our website http://www.adamantvalves.com/ for more information.

One Comment

iptv server

Hello,nice share.