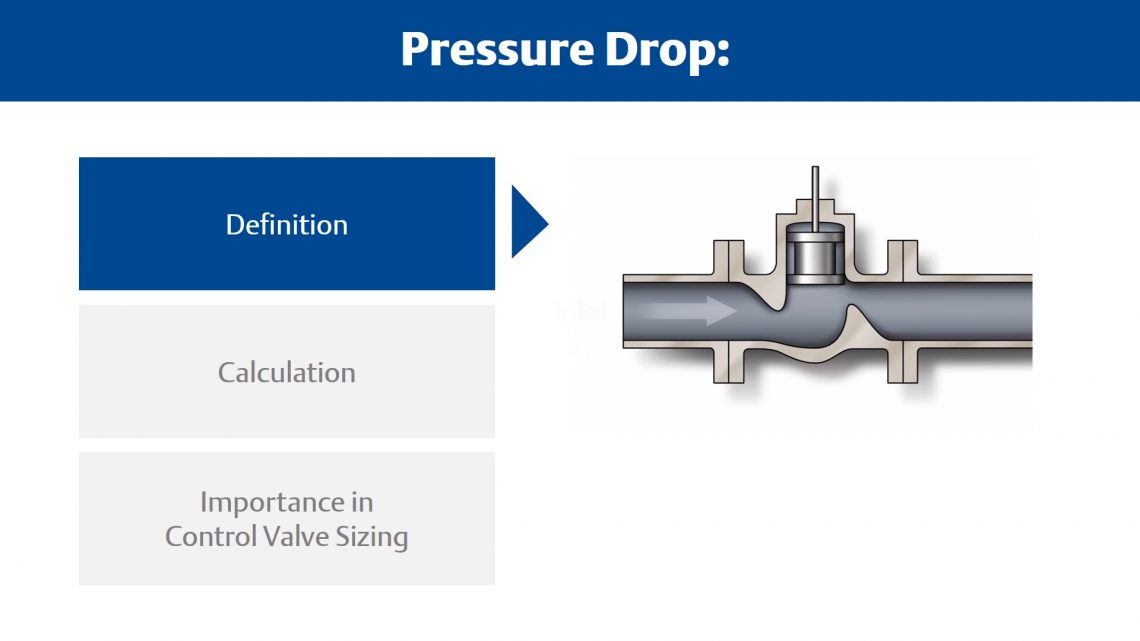

Pressure drop, also known as pressure loss, is an important selection criteria for control valves as it’s used in the sizing calculation. Let’s define the term pressure drop, show how it’s calculated, and discuss why it’s important for engineers designing flow systems.

Definition of Pressure Loss

Pressure drop is the difference in pressure as measured between two points in a pipe with flowing fluid. For a control valve, the pressure drop is the difference between the inlet pressure and the outlet pressure. It varies with the flow.

Calculation of Pressure Loss

The calculation for pressure drop looks like this △P=P1 + P2. The pressure drop is usually measured in pounds per square inch differential or PSID. Inlet or upstream pressure is shown as P1. Outlet or downstream pressure is shown as P2. P1 is measured two pipe diameters upstream of the valve.P2 is measured six pipe diameters downstream of the valve. Your process or instrumentation department will provide these variables.

To calculate the pressure drop across a valve, subtract the outlet pressure from the inlet pressure. For example, if P1 is 3000 psi and P2 is 2000 psi, the pressure drop will equal 1000 psid. If the flow rate is going to vary, repeat the calculation of P1 and P2 at each flow rate.

Importance of Pressure Loss

Pressure drop data is used in the control valve sizing equation and is critical for proper valve selection. Control valve flow is a function of both the pressure drop across the valve and the valve travel. In control valve selection, pressure drop plays a role in determining not only the valve and trim style, but the materials of construction as well.

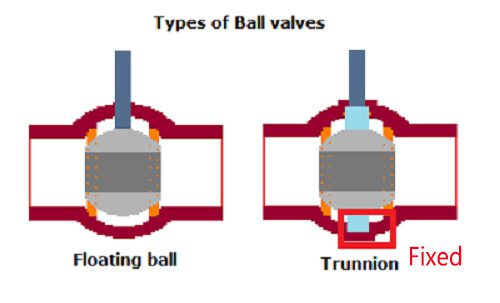

Higher pressure drops generally require highly engineered control valves for good performance. Control valve manufacturers publish charts with maximum pressure drop limits for their control valves. The charts for Emerson’s Fisher control valves can be found in their product bulletins. The maximum pressure drop a control valve can tolerate at shutoff or when partially or fully open is an important selection criteria. Globe control valves are generally superior in both regards because of the rugged nature of their moving parts. Many rotary control valves are limited to pressure drops well below the body pressure rating—especially under flowing conditions—due to the stresses that high-velocity flow imposes on the disk or ball segment.

For more information, please visit https://www.adamantvalves.com/.