What is a ball valve?

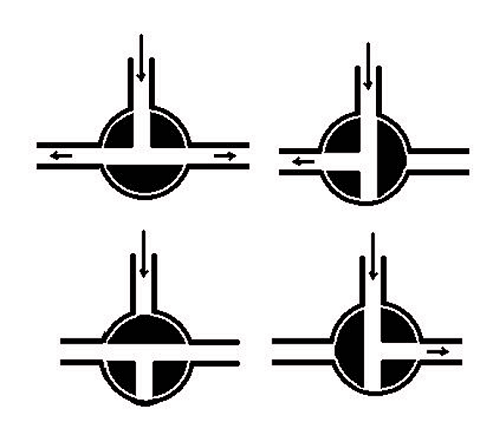

A ball valve is a one-way valve that is opened and closed by pressure on a ball which fits into a cup-shaped opening. Generally, a ball valve has two entries, but there is also 3-way ball valve, as shown below.

A 3-way ball valve has three entries. It may have an L or a T design as shown in the picture below. Depending on your own requirement, you can arrange the entries of the 3-way ball valve in the following three-way.

1. One inlet and two distribute

2. One inlet and one outlet with diverting a flow

3. Straight pass the fluid without No inlet

Ball valves are largely used in the petrochemical, oil refining, energy, offshore drilling, marine, shipbuilding, renewable energies, pulp & paper. They are less widespread in pharmaceutical, bioprocessing, or food and beverage applications as cleaning is not as easy as other types of valves. Therefore, for those industries which have high requirement of cleanness, sanitary ball valves are their best choice.

Ball Valve Pros and Cons

Advantages of Ball valves include:

They can be quickly opened and closed with a quarter turn movement

Ensure a very tight seal without the need of high torque forces

Compact design

Disadvantages include:

Poor regulating and throttling performance

Not suited for slurry applications

May be difficult to clean (side entry design)

Related Blog: Types of Valve and Their Pros and Cons

Ball Valve Comparision

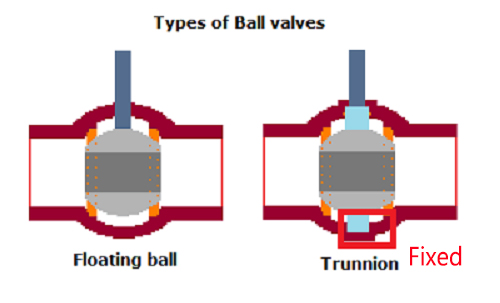

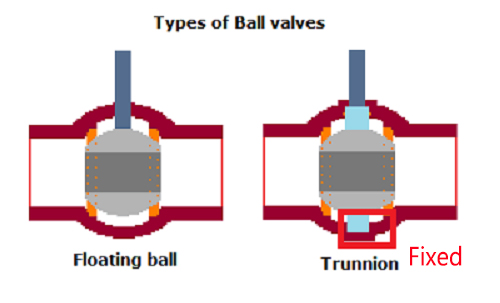

The ball of the ball valve can be a free float or fixed in the valve body. The former is known as floating type whereas the latter type is known as trunnion ball valve.

Appeareance

The floating ball valve and the trunnion ball valve can be easily distinguished in their appearance. If the valve body has a fixed shaft on the bottom, it is a trunnion ball valve; if the ball is free to float inside the valve body, then it is considered a floating ball valve.

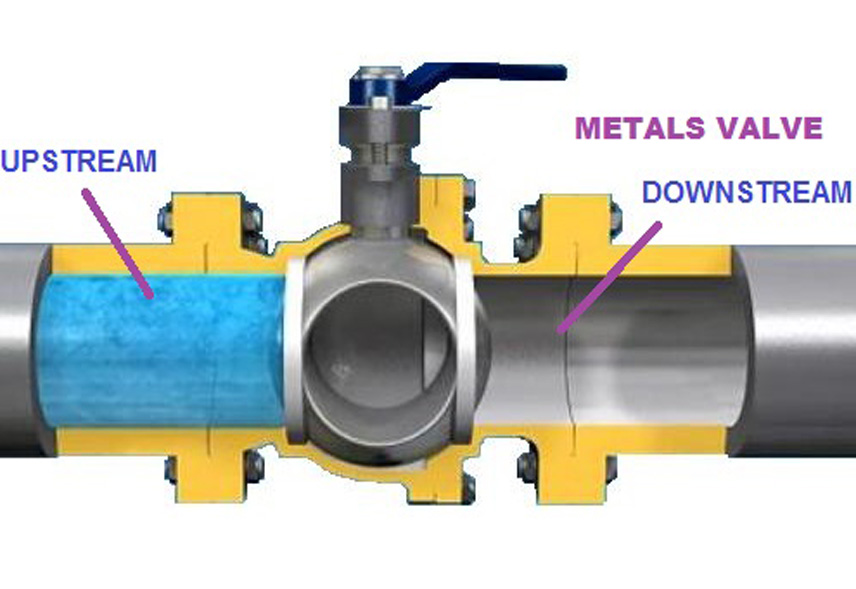

Sealing

Since the ball of the floating ball valve is floating, the ball will move and against the downstream seat under the pressure of the medium, so the seal of the floating ball valve actually belongs to the single-side seal. In contrast, the ball of the trunnion ball valve cannot be moved, so both the two sides of the trunnion ball valve must be sealed.

Working principle

As for the floating ball valve, when the ball valve is closed, the floating ball is pressed against the sealing surface under the action of pressure to realize sealing. As for the trunnion ball valve, when the ball valve is closed, the ball does not produce displacement, but the floating seats will move and press against the ball under the action of the media pressure to realize sealing.

Operating Environment

The floating ball valve is suitable for medium and low pressure and usually has a small diameter. The trunnion ball valve can be used in high pressure conditions and the size can be up to 60 inches.

For more information, please visit http://www.adamantvalves.com/ for more information.