This article will explain to you how the sanitary ball valve works and some of its main components. At the end of the video, it also summarizes the advantages and disadvantages associated with such valves.

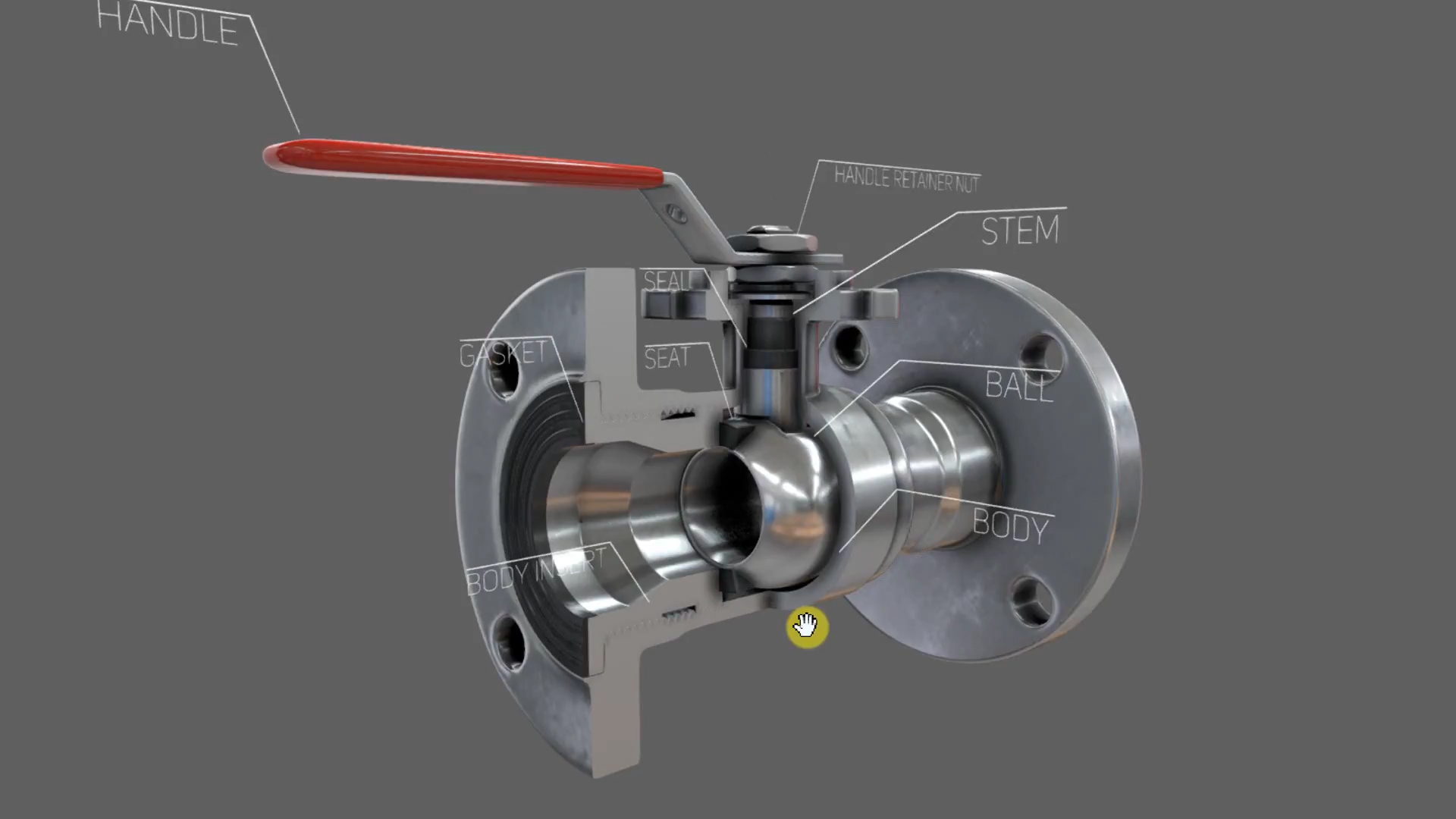

In this gif, we can see the sanitary ball valve on this side, we can see the body. Please note that the body here is slightly larger because this is where the ball is stored.

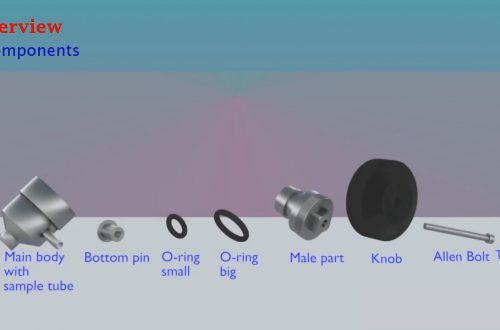

Here we have some ball valves marked with some main components.

The name of the ball valve comes from the type of disc it uses, the ball. We can see the next picture, the ball valve is in the fully open position. We can turn the valve stem to close the valve. The purpose is to stop the flow.

Valves that only rotate the valve 90 degrees are part of the quarter-turn or 90-degree rotary valve series. Like all quarter-turn valves, they operate very fast. You can install a gearbox at the top, a planetary gearbox, but this means you will slow down the drive speed of the valve or what they call response time.

As you can see, the disk is made of metal and looks like stainless steel, as is the body itself. The seat is made of a softer material, which may be Teflon or some kind of elastic material, which may be neoprene or hard rubber. This allows us to press the disk tightly against the seat and we get a very good seal.

There are three different types of ball valves. They are three different types of ball valve. These are the Venturi, reduced and full bore.

A complete ball, the ball itself will have a flow path through it that matches the internal damage of the pipe to which it is attached. This leads us to understand some of the advantages and disadvantages of the ball valve.

Advantage

1) The ball valve can be opened, allowing a completely low-pressure drop across the valve, which means that the flow through the valve is virtually unlimited.

2) The valve can be rotated very quickly – it only requires a quarter-turn of the turn.

3) The ball valve itself is relatively inexpensive and has low maintenance costs.

4) It does not require lubrication

5) The ball seal is very good on the seat, which reduces the possibility of leakage.

Disadvantage

1) It is very poor in terms of throttling.

2) Valves are not suitable for high-temperature applications.

For more information about sanitary valves, please visit https://www.adamantvalves.com/.