The sanitary ball valve was introduced in the 1950s and has rapidly developed into a major valve category. In industrially developed countries, the use of ball valves is increasing year by year. It is widely used in the chemical, paper, pharmaceutical, water conservancy, electric power, municipal, steel and other industries.

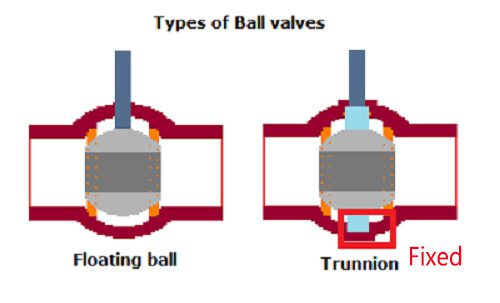

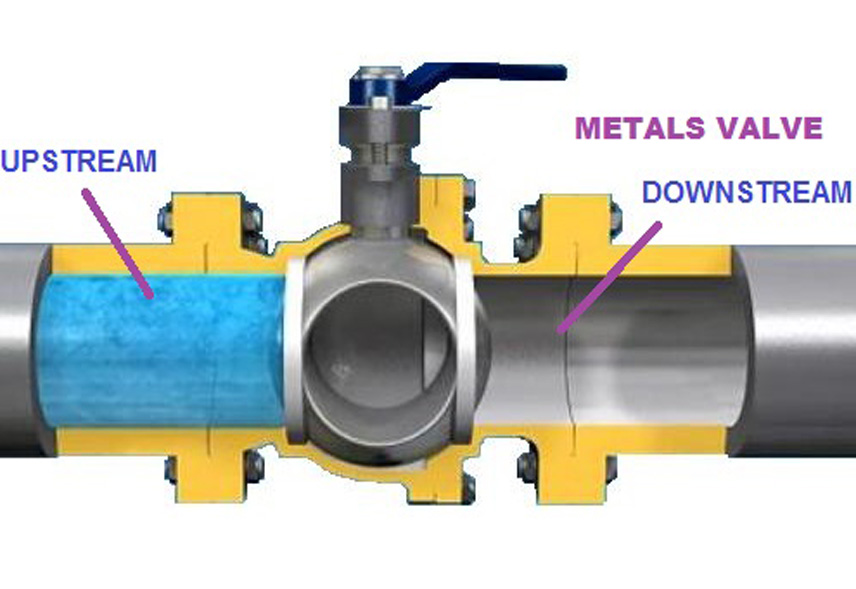

The cock of the ball valve is a sphere that can be rotated 90 degrees. It has a circular through-hole or passage through its axis. The ball valve is mainly used in the pipeline to cut, distribute and change the flow direction of the medium. The ball valve is most suitable for use as a switch or shut-off valve. When using an electric ball valve, in addition to the pipe parameters, special attention should be paid to the environmental conditions in which it is used.

The sanitary plug valve is a fast-switching, straight-through valve that can also be used for media with suspended particles due to the wiping action between the rotary seal faces and the complete contact with the flowing medium during the full opening. Another important feature of the plug valve is that it is easy to accommodate multi-channel construction so that one valve can achieve two, three, or even four different flow paths. This simplifies the design of the piping system, reduces the amount of valves used, and some of the connecting accessories needed in the equipment.

When used as a shut-off valve, the plug valve has a slightly better adjustment than the ball valve. The sealing surface of the plug valve is much larger than the ball valve, so its sealing effect is good, but it also brings the defect that the torque is too large and the action is not flexible enough. And the conventional positive cock structure is difficult to achieve a large diameter due to the weight of the cock itself.

When used as a regulating valve, the two are also comparable, and appropriate holes can be made in their rotating bodies for adjustment.

Therefore, plug valves are generally used for applications where sealing is required, while ball valves can be used in more and wider industrial applications.

For more information, please visit https://www.adamantvalves.com/.