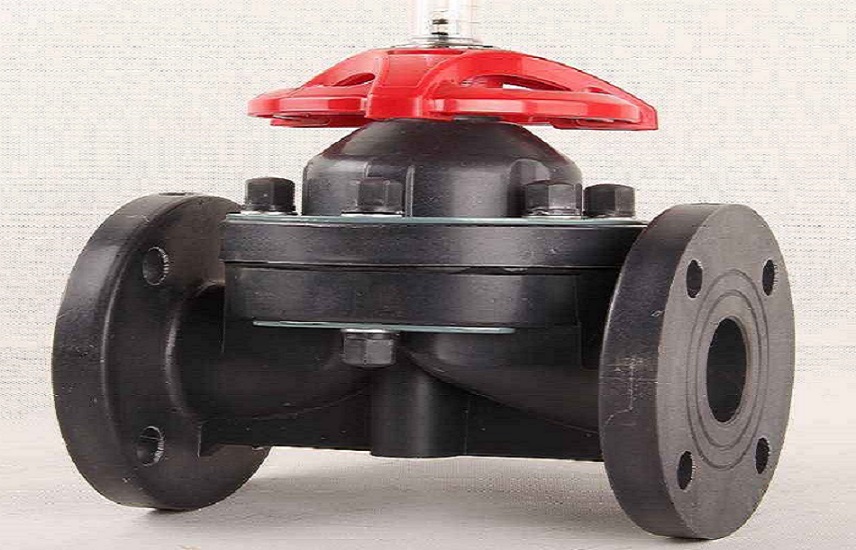

The diaphragm valve, structurally different from the general valve, is a special type of shut-off valve. Its opening and closing member is a diaphragm made of soft material (elastic, corrosion-resistant, non-permeable material such as rubber and plastic), which separates the valve body cavity from the bonnet cavity and the driving member.

Diaphragm valves can be used for low pressure, low temperature, corrosive and suspended materials. They have the advantage of simple structure, good sealing and anti-corrosion performance, and low fluid resistance, so it is widely used in various fields.

Diaphragm Valve Classification

-According to the structure, there are ridge type, cut-off type, ram type, etc.;

-According to the driving method, there are manual, pneumatic and electric;

-According to the diaphragm material, there are rubber diaphragm valves, fluorine-lined diaphragm valves, unlined diaphragm valves, plastic diaphragm valves.

Working Principle

Diaphragm valves use a corrosion-resistant lining valve body and a corrosion-resistant diaphragm to replace the valve plug components, and control the medium by moving the diaphragm. If you have trouble understand the working principle of diaphragm valves, please check the “video lesson” below.

The valve body of the diaphragm valve is usually made of cast iron, cast steel, or cast stainless steel, and is lined with various corrosion-resistant or wear-resistant materials,rubber and Teflon. The lining diaphragm has strong corrosion resistance and is suitable for strong corrosive media such as strong acid and alkali.

Pros and Cons

The diaphragm valve has a simple structure, small fluid resistance, and large flow capacity compared with other types of valves of the same specification; it can be used for high viscosity and suspended particle media; the diaphragm separates the medium from the upper cavity of the valve stem, so there is no filler and the medium will not leak.

However, due to the limitations of the diaphragm and the lining material, the pressure resistance and temperature resistance of the diaphragm valve are poor. It is generally only suitable for environments with a nominal pressure of 1.6 MPa and temperatures below 150 °C.

Sanitary diaphragm valve

Compared to ordinary diaphragm valves, sanitary diaphragm valves have higher specifications, and they are safer and more hygienic. The main material of sanitary diaphragm valves is stainless steel. Therefore, it is widely used in food, beverage, dairy, brewing, pharmaceutical industries, etc.

Please visit our website http://www.adamantvalves.com/ for more information.

5 Comments

Pingback:

Pingback:

Pingback:

Pingback:

valmik patel

Nice! Great content thank you for sharing with us and I have learned from this article.