1. Action sensitivity and reliability

This refers to the sensitivity of the valve to respond to changes in medium parameters.

Actuator

2. Wormgear actuator

A device that uses a worm gear mechanism to open, close or adjust a valve.

3. Pneumatic actuator

A pneumatic actuator is a drive device that opens, closes or adjusts the valve with air pressure.

4. Hydraulic actuator

The drive device that opens, closes or adjusts the valve with hydraulic pressure.

5. Connection dimensions

Dimensions of valve and pipe connections.

6. Disc

A general term for a part used to cut off or regulate the flow of media, such as the gate in the gate valve, the disc in the throttle valve, etc.

7. Dimension of the connecting channel

Structural dimensions of the assembly connection between the opening and closing parts and the valve stem.

Flow

8. Flowing medium

After the medium flows through the valve, there will be a pressure loss (that is, the pressure difference before and after the valve), that is, the valve has a certain resistance to the flow of the medium, and the medium consumes a certain amount of energy to overcome the resistance of the valve. Considering energy saving, when designing and manufacturing the valve, the resistance of the valve to the flowing medium should be reduced as much as possible.

9. Flow area

Refers to the minimum cross-sectional area between the inlet end of the valve and the sealing surface of the valve seat (but not the “curtain” area), used to calculate the theoretical displacement without any resistance.

10. Flow diameter

Corresponds to the diameter of the runner area.

11. Flow characteristics

In a stable flow state, when the parameters such as the inlet pressure remain unchanged, the functional relationship between the outlet pressure of the pressure-reducing valve and the flow rate.

12. Flow characteristics derivation

In a stable flow state, when the parameters such as the inlet pressure remain unchanged, the change value of the outlet pressure caused by the change of the flow rate of the pressure reducing valve.

13. General dimensions

The opening and closing height of the valve, the diameter of the handwheel and the connection size, etc.

14. Gland

Parts used to compress packing to achieve sealing.

15. Hammer blow handwheel

A handwheel structure that uses the impact force to reduce the valve operating force.

16. Hot condensate capacity

The maximum amount of condensate that can be drained from trap 1 at a given differential pressure and temperature

17. Model

Numbering of valves according to type, transmission mode, connection form, structural characteristics, material of valve seat sealing surface and nominal pressure.

18. Opening and closing force and opening and closing torque

Opening and closing force and opening and closing torque refer to the force or torque that must be exerted by the valve to open or close. During the opening and closing process, the required opening and closing force and opening and closing torque vary, and the maximum value is at the final moment of closing or the initial moment of opening. The valve should be designed and manufactured to reduce its closing force and closing torque.

19. Opening and closing speed

The opening and closing speed is expressed by the time required for the valve to complete an opening or closing action.

20. Packing

Packing into a stuffing box (or stuffing box) to prevent leakage of media from the valve stem.

21. Packing seat

The parts that support the packing and keep the packing sealed.

Seal

22. Sealing face

The opening and closing parts are closely fitted with the valve seat (valve body), and act as two contact surfaces for sealing.

23. Sealing performance

The sealing performance of the valve refers to the ability of its sealing parts to prevent the leakage of the medium, which is the most important technical performance index of the valve.

24. Seal test

A test to check the performance of the opening and closing parts and the valve body sealing pair.

25. Back seal test

A test to check the sealing performance of the valve stem and the bonnet sealing pair.

26. Seal test pressure

The specified pressure when the valve is subjected to a tightness test.

27. Service life

It indicates how durable the valve is. It is an important performance index of the valve and has great economic significance. It is usually expressed by the number of times of opening and closing that can ensure the sealing requirements, and it can also be expressed by the use time.

28. Steam loss

The amount of live steam leaking from the trap per unit time.

29. Strength performance

The strength performance of the valve refers to its ability to withstand the pressure of the medium. The valve is a mechanical product that is subjected to internal pressure, so it must have sufficient strength and rigidity to ensure long-term use without rupture or deformation.

30. Suitable medium

The medium to which the valve can be applied.

31. Suitable temperature

The temperature range of the medium for which the valve is suitable.

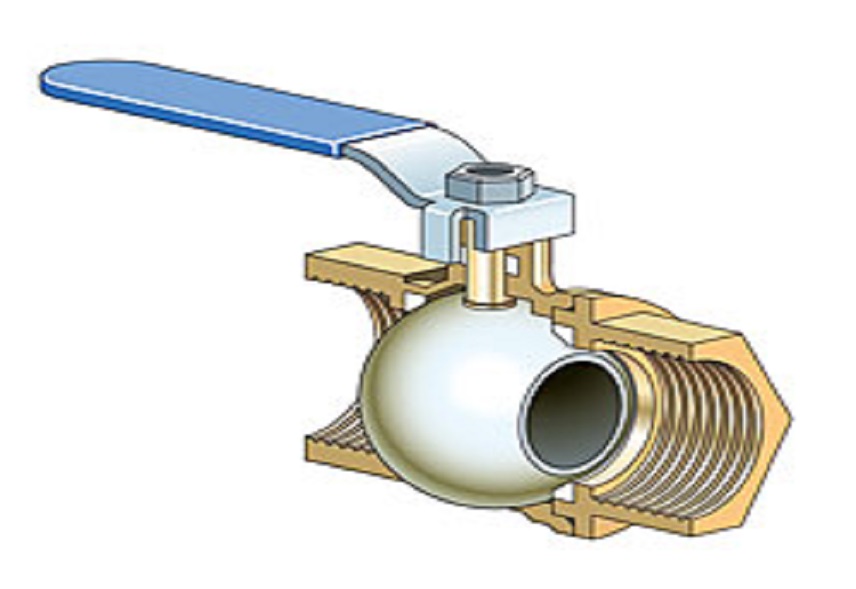

Types of Valve

32. Type

Classification of valves by purpose or main structural features.

33. General valve

Valves commonly used on pipelines in various industrial enterprises.

34. Self-acting valve

A valve that operates by itself depending on the ability of the medium (liquid, air, steam, etc.) itself.

35. Actuated valve

Valves that are operated manually, electrically, hydraulically or pneumatically.

36. Type of connection

Various methods used to connect the valve to the pipeline or machine equipment (such as flange connection, threaded connection, welding connection, etc.).

37. Yoke

On the valve cover or valve body, the parts used to support the stem nut and transmission mechanism.

For more information about sanitary valves, please visit http://www.adamantvalves.com/.