Gate Valve

The gate valve is one of the most commonly used on-off valves that utilizes the gate to turn on (fully open) and cut off (fully closed) the media in the pipeline. The gate is lifted and lowered in a plane perpendicular to the center line of the gate seat passage and cut the medium in the pipeline like a gate, so it is called a gate valve. This type of valve cannot be used for throttling.

Feautures:

1. The flow resistance is small. The inner medium passage of the valve body is straight so the medium flows in a straight line and the flow resistance is thus small.

2. It is more labor-saving when opening and closing compared with the shut-off valve. Because the direction of movement of the gate is perpendicular to the direction of flow of the medium, whether it is open or closed.

3. The medium can flow in any direction on both sides because the gate valve channels are symmetrical on both sides. So it is easy to install.

4. The length of the structure (the distance between the two connecting end faces of the casing) is small.

5. The sealing surface is easy to wear and affect the service life. When opening and closing, the two sealing surfaces of the gate and the valve seat rub against each other, and it is easy to cause abrasion and abrasion under the action of the medium pressure, which affects the sealing performance and shortens the service life.

6. There are many contact sealing surfaces, and the processing is complicated. In particular, the sealing surface on the gate seat is not easy to process, and there are many parts.

Shut-off Valve

The shut-off valve is a closed-circuit valve that uses the valve flap to move along the center line of the valve seat (valve) passage to control the opening and closing of the pipeline. The shut-off valve is generally suitable for transporting liquid and gaseous media within the specified standard range under various pressures and various temperature conditions, but it is not suitable for liquid containing solid precipitated or precipitated crystals. In the low-pressure pipeline, the shutoff valve can also be used to regulate the flow of media. However, due to structural constraints, the nominal diameter of the shut-off valve is below 250mm. If the pressure is high on the pipeline and the flow rate is high, the sealing surface will wear quickly. Therefore, when regulating the flow rate, a throttle valve is still preferred.

Feautures:

1. The wear of the sealing surface is not large, so the work is more reliable and the service life is long.

2. The sealing surface area is small and the structure is relatively simple. The time required for manufacturing the sealing surface and the precious materials required for the sealing ring are less than those of the gate valve.

3. It is more laborious to open and close the opening and closing torque. When closed, the direction of motion of the valve flap is opposite to the direction of motion of the medium, so the opening and closing torque is large.

4. The flow resistance is large. The flow resistance of the shut-off valve is the largest among all types of block valves.

5. The medium flow direction is unidirectional.

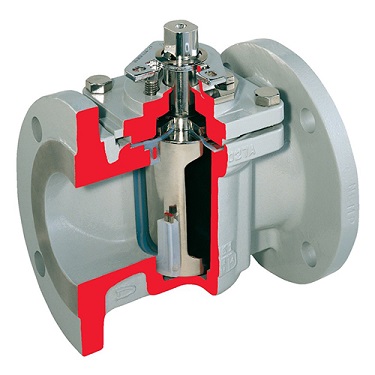

Butterfly Valve

The butterfly valve is a rotary valve that turns the opening and closing of the passage by turning the disc-type opening and closing member by 90°. Most butterfly valves are available for media with suspended solid particles.

Feautures:

1. Small size, simple structure and light weight.

2. Easy to operate; fast opening and closing speed.

3. Because the butterfly valve uses rubber as the sealing ring, the compression, resilience and sealing are good.

4. The valve flap can be opened between 15° and 70° for sensitive flow control.

5. Operating torque and fluid resistance are small. The fluid resistance of the butterfly valve is less than that of any other types of valves except ball valves.

6. Due to the limitation of the sealing material, the operating pressure and a working temperature range of butterfly valve are small.

Check valve

The check valve is a valve used to prevent backflow of the medium in the pipeline. It opens when the medium is flowing downstream and automatically shuts off when the medium flows back. It is generally used in pipes that do not allow the media to flow in the opposite direction to prevent backflowing media from damaging equipment and parts. In the pipeline, the check valve and the closed-circuit valve are often used in series due to the poor sealing of the check valve. The foot valve is also a check valve that must be submerged in water. It is installed especially at the front end of the suction pipe of a water pump which cannot be self-priming or without vacuum pumping.

Plug valve

A plug valve is a valve in which the opening and closing member (a plug with a passage) is rotated about a center line of a valve body to open or close. This type of valve is widely used in media lines with a delivery temperature of ≤120 °C. It is less used at high temperatures because the plug and the case are thermally expanded. The plug valve can be used to cut off the medium flow, and can also be used as a regulating valve, a three-way valve, a four-way valve, and can also be used as a distribution valve or to change the flow direction of the medium.

Feautures:

1. The resistance is small when the medium passes.

2. Simple structure, light weight, small size and convenient operation.

4. It is laborious to turn the plug because the sealing surface is large.

5. It can be installed horizontally or vertically.

6. The cone surface of the valve body and the plug contact is large, so it is easy to wear during use and affects the seal.

Throttle valve

The throttle valve regulates the flow and pressure of the line medium by changing the cross-sectional area of the valve passage. The smaller the cross-sectional area, the greater the resistance to the medium being crossed and the smaller the flow. The throttle valve can not be used as a shut-off valve because it generally does not have a sealing surface. Even it does have a sealing surface, the sealing surface is quickly eroded and loses its sealing property under the action of a high-speed medium.

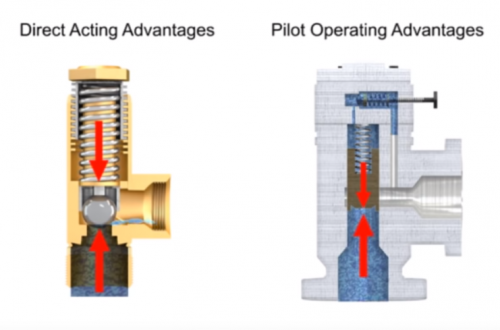

Safety valve

The safety valve is a protection valve. It is installed on pressurized equipment, vessels, and piping. The safety valve is normally closed by an external force. When the pressure of the protected pipeline medium exceeds the specified value, the valve flap automatically opens to discharge excess medium to lower the pressure; and when the medium pressure returns to within the specified value, it automatically closes. The safety valve acts as a conduit to ensure safe operation of the system and equipment. Safety valves are widely used in boilers, compressor air reservoirs, high-pressure vessels and pipelines, etc., where the working pressure of the medium may exceed the allowable value and cause a risk of bursting.

Pressure relief valve

The pressure relief valve can reduce the pressure of the medium in the equipment container or in the pipeline to a prescribed pressure. It can maintain the outlet pressure within a certain range in the case where the inlet pressure changes and the flow outlet changes.

Founded in 2002, Adamant Valves is a professional valves manufacturer specialized in manufacturing a wide range of sanitary valves, which have much higher performance than normal industrial valves. Please visit http://www.adamantvalves.com/ for more information.