Diaphragm valve

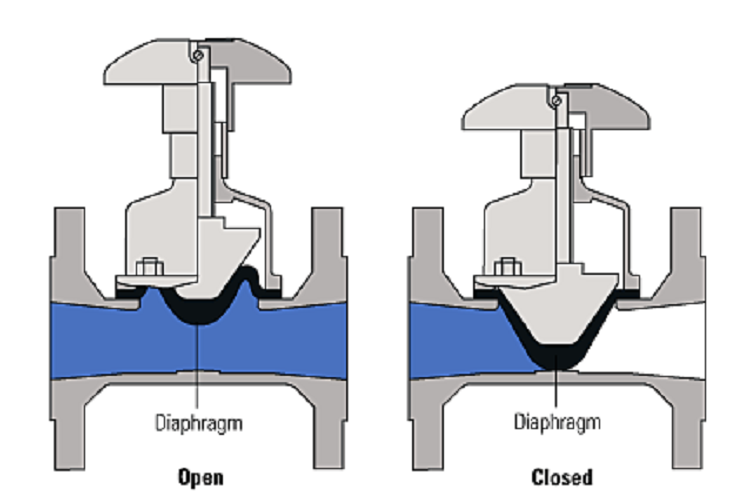

Diaphragm valves consists of a valve body with two or more ports, a diaphragm, and a “weir or saddle” or seat upon which the diaphragm closes the valve. The diaphragm valve was initially developed for industrial applications and pipe-organs. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods. What’s more, sanitary diaphragm valves are specially designed with the highest standard for applications in manufacturing of medicine and food.

Diaphragm valves use a corrosion-resistant lining valve body and a corrosion-resistant diaphragm to replace the valve plug components, and control the medium by moving the diaphragm. When the diaphragm is lifted up, the passage is opened; when the diaphragm is lowered, it is pressed against the valve body and the valve is closed.

Pros

1) Simple structure, consisting of only three parts: a valve body, a diaphragm and a cover

2) During the operation, the medium only contacts with the diaphragm, so the valve is not easily contaminated.

3) Suitable for transporting corrosive, viscous liquids

Cons

1) Not suitable for larger pipe diameters

2) Poor pressure resistance and temperature resistance

Globe Valve

A globe valve is a type of valve used for regulating flow in a pipeline. Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug can be screwed in to close (or shut) the valve. In globe valves, the plug is connected to a stem which is operated by screw action using a handwheel in manual valves. Typically, automated globe valves use smooth stems rather than threaded and are opened and closed by an actuator assembly.

Advantages

1) Simple structure; convenient manufacturing and maintenance

2) The sealing surface is not easy to be worn or scratched, so the sealing property is good and the service life is long.

3) The opening and closing time is short and the valve height is small.

Disadvantages

1) Large circulation resistance

2) It is more difficult to open and close

3) Media flow direction is limited

For more information, please visit http://www.adamantvalves.com/.

One Comment

Rebecca Gardner

It was interesting when you talked about how diaphragm valves have a lining that’s resistant to corrosion. I’ve been trying to learn more about the different types of valves so I can help my husband make a choice about the right one to buy. Do you have any information about the way solenoid valves are lined?