Valve Characteristics The use characteristics of the valve determine its main performance and use range. The use characteristics of the valve include: valve category (closed-circuit valve, regulating valve, safety valve, etc.), product type (gate valve, globe valve, butterfly valve, ball valve, etc.), valve main parts (valve body, valve cover, valve stem, valve disc, sealing surface) material, valve rotation method, etc. The structural characteristics of the valve determine the installation, repair, maintenance and other methods of the valve. The structural characteristics include: the structural length and overall height of the valve, the connection form with the pipeline (flange connection, threaded connection, clamp connection, external thread connection, welding end connection, etc.), the…

-

-

Application of Sanitary Butterfly Valve in Thermal Electric Water Heater

The application of stainless steel sanitary butterfly valves in the food and beverage industry is mainly reflected in their application of thermal electric water heaters. Thermal Electric Water Heater The thermal electric water heater is mainly composed of a heating trough plate, pressure sensor, power conditioner, water volume regulating faucet, water inlet pipe, and water outlet pipe components, among which the heating trough plate is the key component of the instant electric water heater. The heating tank consists of a tank weight, a sealing ring, a cover and an electric heating element. The electric heating element is located in the groove of the groove plate, which is also generally called…

-

Development History of Butterfly Valve

Butterfly valve developing history In the 1930s, the United States invented butterfly valves. This valve has a small operating torque, a small installation space and a light weight. Taking DN1000 as an example, the butterfly valve is about 2T, but the gate valve is as heavy as 3.5T. The butterfly valve is easy to combine with various driving devices, and has good durability and reliability. The relationship between the opening of the butterfly valve and the flow rate changes substantially linearly. If used to control flow, its flow characteristics are also closely related to the flow resistance of the piping. For example, if the diameters, forms, etc. of the two…

-

Sanitary Butterfly Valve Image Gallery

What is the sanitary butterfly valve? Sanitary butterfly valve, also called hygienic butterfly valve, is a type of flow control device. It is a form of Butterfly Valves whose valve body, valve disc, and other components are fabricated out of stainless steel. Sanitary butterfly valves are used to make a fluid start or stop flowing through a section of pipe for these devices in applications such as food and beverage processing, personal care, biomedical, or pharmaceutical industries. Type: Butterfly ValveReference No.: AV-1Sizes: 1″ – 4″End Types: Tri-Clamp, Pull HandleGrades: 304 – 316LOperation: Manual, Pneumatic Adamant Valves sanitary butterfly valves uses: AV-1 series stainless steel sanitary butterfly valves are widely used to the petroleum, metallurgy, plumbing, food, bio-pharmaceutical…

-

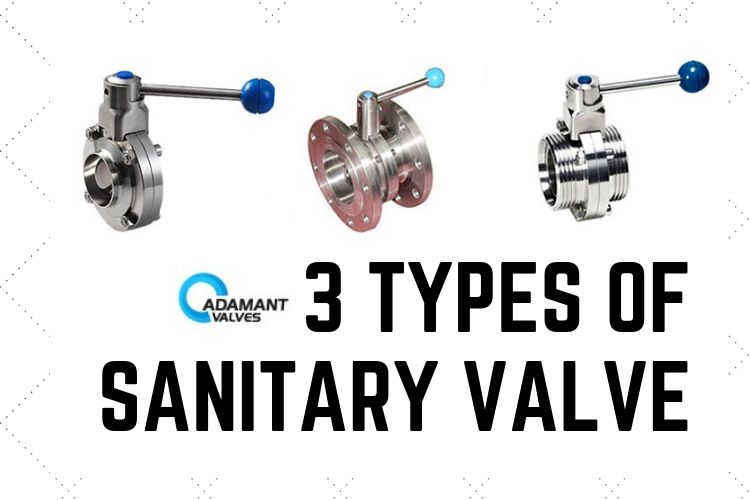

3 Types of Sanitary Butterfly Valves

A Quick Look at These Three Types of Sanitary Butterfly Valve. Sanitary Butt Welded Butterfly Valve, Sanitary Thread Butterfly Valves and Sanitary Flange Butterfly Valves. Sanitary Butt Welded Butterfly Valve The Sanitary Butt Welded Butterfly Valves are triple offset structure and suitable for high temperature, high pressure, corrosion, etc. Its are quarter-turn valves which are used for isolating or regulating flow. They are favored for being lighter in weight, requiring less support and are suitable for water and gas, which makes them useful across industrial, mining and power applications. The butt-weld butterfly valve has various advantages such as good sealing performance, convenient operation, and quick opening and closing. They have no flanges, making the…